The Circularity Race: How Fashion for Good is Changing the Footwear Industry

Credit: GoodLifeStudio

17 September 2025

Picture this: if you lined up every single shoe produced globally in a single year, the chain would wrap around Earth’s equator nearly 300 times. That’s 23.8 billion pairs of shoes manufactured annually, and here’s the devastating kicker: 90% of them are destined for landfills or incineration.

Footwear represents one of fashion’s toughest sustainability challenges: shoes are made from multiple tightly bonded materials (including rubber, foam, leather, and textiles), with often more than 60 components, making them difficult to disassemble, recycle, or repurpose. And even if disassembly were feasible (through breakthrough innovations), there’s another problem: recycling infrastructure for footwear barely exists, as most facilities are designed to handle clothing, not shoes. Add to that the lack of standardised take-back systems, and the result is a global stream of used footwear piling up, with nowhere to go.

To begin addressing these interlinked challenges, a series of collaborative projects has emerged, focusing on everything from circular design principles to waste mapping and recycling innovation.

Source: Fashion for Good

Source: Fashion for Good

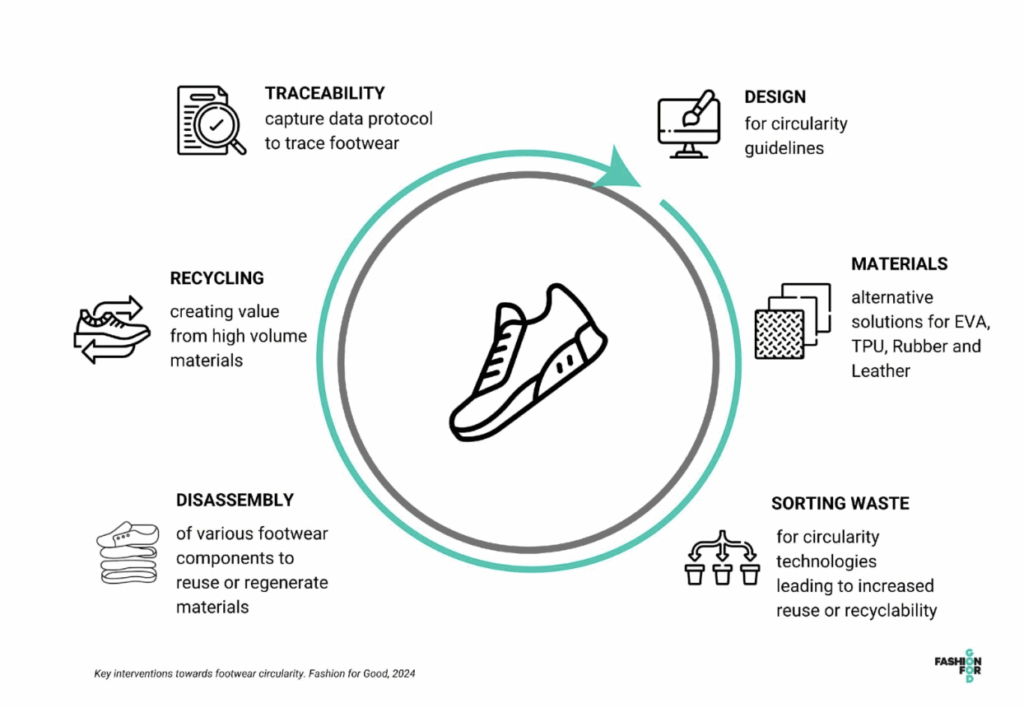

BUILDING THE SYSTEM: SIX INTERVENTION POINTS

Before we dive into pilots and projects showing what is possible, we need to work on building the systemic architecture that can support circularity at scale. This framework identifies the six critical intervention points we believe that (together) form a holistic approach to transforming the footwear industry.

- Design: embedding circularity at the start

Circular footwear begins at the drawing board. Establishing clear guidelines for circular design is foundational, influencing everything from material choice to construction methods. Design plays a make-or-break role in whether shoes can be disassembled and recycled, or whether they’re destined for landfill from the outset. - Materials: rethinking the building blocks

Many of today’s shoes rely on materials like EVA, TPU, rubber, and leather, often used in combinations that complicate recycling. Innovation is needed not only in developing alternative materials that can reduce the environmental impact of footwear waste from its production, but also in selecting combinations that preserve performance while enabling recycling. - Sorting Waste: unlocking reuse and recyclability

Without effective waste sorting systems, even recyclable shoes can end up in the landfill. Investing in technologies that can identify and separate shoes by material type or construction method is critical to increasing the volume of footwear that can be recovered, reused, or recycled. - Disassembly: breaking shoes down to build them back up

Shoes are extremely hard to take apart. Developing solutions to disassemble components (manually, mechanically, or chemically) opens up possibilities for material recovery. Whether it’s separating foams, textiles, or reinforcements, disassembly is the gateway to reuse. - Recycling: recovering value from high-volume waste

Recycling can be an incredible source of value. By transforming high-volume footwear materials into usable outputs (like rubber granules, foam padding, or base materials for new products), recycling becomes a core enabler of circularity, and not just a fallback. - Traceability: capturing data across the value chain and end-of-use

Circular systems depend on data. A standardised traceability protocol (from production through to end-of-use) helps track what shoes are made of, how they’re used, and where they end up. This information is key to informing design, enabling sorting, supporting policies and ensuring materials go where they can do the most good.

Credit: vladimirsukhachev

BUILDING TOMORROW’S FOOTWEAR SYSTEM: INNOVATION

-

- Showing what’s possible: the FastFeetGrinded Pilot

#SortingWaste #Recycling #Disassembly

While systemic change takes time, pilots show what’s possible now: FastFeetGrinded is a Fashion for Good innovator that engaged in one such example, first of its kind in footwear, in a collaboration aimed at testing mechanical recycling of post-consumer shoes. This approach breaks down old footwear into material streams like granulated rubber, foam, and textiles.

The project worked with brands (adidas, Inditex, Target, Zalando) to collect used shoes, then processed them through FastFeetGrinded’s unique recycling setup. The result? Recovered materials that can be repurposed for new products, from flooring to furniture components and potentially even new shoes.

- Showing what’s possible: the FastFeetGrinded Pilot

-

- Transforming the post-consumer footwear waste game: Closing the Footwear Loop

#Design #Materials #Traceability

One of the biggest barriers to circularity is what we don’t see: where used shoes go, how they’re sorted (if at all), and what stands in the way of recovery. The Closing the Footwear Loop project, with Fashion for Good bringing together 17 major brands, is set out to map this under-explored terrain, conducting one of the most extensive analyses of post-consumer footwear waste in Europe. All of this, while testing and validating the most promising technologies and business models for the end-of-use of footwear.

But the project doesn’t stop at diagnostics. It aims to establish a comprehensive roadmap for circular footwear design for improvement, addressing circular and safe inputs and materials, recyclability, durability and repairability.

- Transforming the post-consumer footwear waste game: Closing the Footwear Loop

- Designing from the beginning, from the sole up: The Next Stride: Bio-based Materials for Footwear Soles

#Materials #Disassembly

Circularity in footwear isn’t just about what happens at the end: it’s about building shoes from the start with their second life in mind. The Next Stride represents Fashion for Good’s most ambitious foray into bio-based material innovation for footwear soles: this project tackles one of the industry’s most persistent challenges, including replacing conventional fossil-fuel-derived materials like EVA, PU, TPU, rubber, and TPR with sustainable alternatives that don’t compromise on performance.

Through rigorous assessment and benchmarking of bio-based polymers and polymer blends, the project aims to validate these materials’ potential for sole applications while conducting comprehensive Life Cycle Assessments to understand their true environmental impact. Perhaps most critically, The Next Stride addresses the elephant in the room: cost. By exploring optimisation opportunities to reduce the price premium that currently limits brand adoption, the project seeks to generate the market signals necessary to justify large-scale investments in bio-based footwear materials.

Always on the lookout for the most breakthrough innovation

#Footwear #Innovation

This is just one step in a broader impact that Fashion for Good is driving: we continue to scout pioneering innovations in footwear, from biobased materials and mono-material construction to modular design and advanced sorting technologies. By identifying promising solutions and connecting them with industry partners, we aim to unlock new pathways to circularity and scale transformation across the entire footwear value chain.

Other Articles

Fashion for Good Launches “Beyond50 Denim” to Address Hemp Integration Barriers In Global Denim Production

Fashion for Good Unveils “The Next Stride”, A New Footwear Project To Replace Fossil Fuel Material With Bio-based Sole Innovation