Journey to Scale: Circ

Image by Circ.

21 June 2025

Through our global Innovation Platform, Fashion for Good supports critical innovations on their journey to scale, providing hands-on project management, access to funding and expertise, and collaborations with brands and manufacturers to accelerate implementation in the fashion supply chain. In this series, we are proud to introduce some of the groundbreaking innovators who are driving the change to make fashion a force for good.

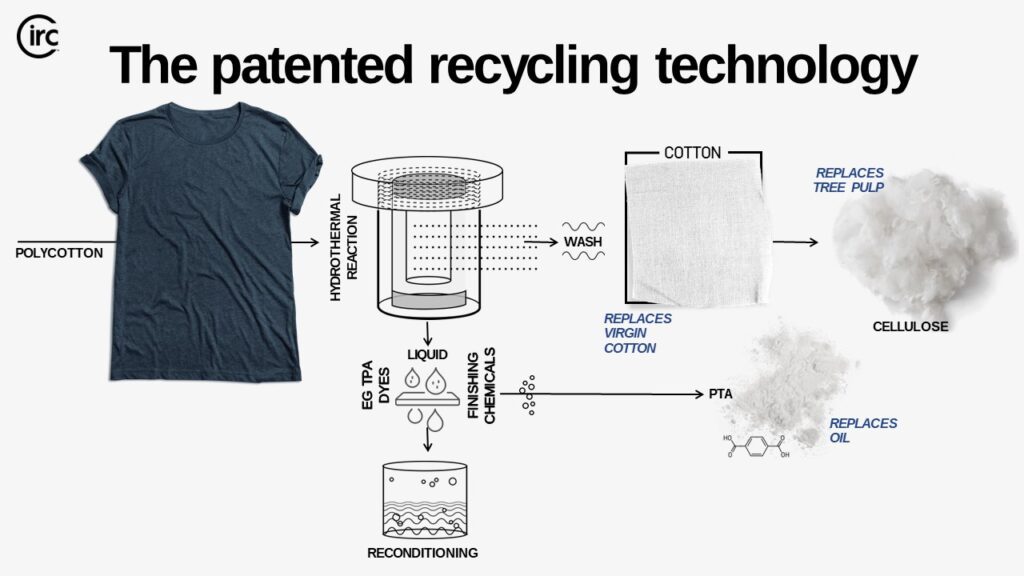

Currently, a large percentage of textiles end up in landfills or are incinerated, rather than being recycled or reused. Circ’s technology offers a solution to this problem by recycling polycotton — what the majority of our clothes are made of — into materials that can be re-entered into the fashion supply chain to make new clothing. The innovator’s hydrothermal process takes textile waste and turns it into materials that can be reused.

By separating synthetic fibres (like polyester) from cellulosic content (like cotton, bamboo, lyocell, viscose, etc), they are able to recover the majority of the raw materials in textile waste, producing high-quality fibre and reducing our reliance on virgin materials.

KEY MILESTONES

-

2011

Tyton Biosciences is launched to investigate ways of creating biofuels from modified tobacco plants.

-

2017

Tyton Biosciences pivots to focus on the textile industry.

-

2018

Tyton Biosciences joins Fashion for Good for bespoke support on their roadmap to scale.

-

2020

Tyton BioSciences closes $8 million Series A funding round led by Tin Shed Ventures (the investment arm of Patagonia) with additional investment from Marubeni America, Card Sound Capital and Alante Capital.

Tyton BioSciences takes part in the Fashion for Good’s “Full Circle Textiles Project: Scaling Innovations in Cellulosic Recycling”.

Tyton BioSciences rebrands to Circ.

-

2021

CIRC and ANDRITZ partner to commercialise recycling technology.

-

2022

Circ raises over $30 Million in Series B funding led by Breakthrough Energy Ventures (BEV), with additional investment from Inditex, Milliken, Lansdowne, Temasek.

-

2023

Zara launches a first-of-its-kind capsule collection using recycled poly-cotton from Circ.

Circ and Acegreen partner to manufacture fibre from reclaimed poly-cotton.

Vivobarefoot partners with Circ to pioneer chemical recycling in footwear.

Circ is named one of 15 finalists for the Earthshot Prize, unveiled by Prince William.

Mara Hoffman releases “The Dress That Changes Everything” using Circ Lyocell made from textile waste.

-

2024

First Utilisation of Recycled Cotton and Polyester Materials of U.S. Company Circ, Inc. in Marubeni Japanese Branded Products

Circ inked a deal with India’s Aditya Birla Group (via Birla Cellulose) to supply at least 5,000 tonnes/year of pulp from its first commercial-scale facility for five years.

Circ announces the launch of their second capsule collection with clothing manufacturer Zara, completely made from Circ Lyocell.

-

2025

Circ Launches ‘Fibre Club’ With Bestseller, Eileen Fisher And Everlane

$25M funding round led by Taranis, with backing from Inditex.

TIME 2025: Circ named among World’s and America’s Top Greentech Companies.

Strategic partnerships announced with Acegreen and Selenis to scale polyester recycling in Europe.

Bloomberg Pioneers Award 2025: Circ recognised as a top climate innovator.

Retail launch: Circ Lyocell debuts with Zalando’s Anna Field, featuring 40% recycled polycotton in retail garments.

This is a high-level process overview of Circ’s patented poly-cotton recycling process. Image by Circ.

WHAT’S NEXT

By 2030, Circ aims to recycle 10 billion garments, representing 10% of the global apparel market, which will save more than 100 million trees.

LINKS

Website: https://circ.earth/

Learn more about Circ’s involvement in the Fashion for Good Full Circle Textiles Project.

Other Articles

Fashion for Good Launches “Beyond50 Denim” to Address Hemp Integration Barriers In Global Denim Production

The Circularity Race: How Fashion for Good is Changing the Footwear Industry